-

Posts

27 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Everything posted by CossiEst

-

No nines this year, as i went to the lineup, my oil return pump failed and that was the end of it. there were some other races this summer but i had no time to participate in them. In the winter i made a new exhaust because the old one scraped occasionally and i didn't want to rise the back end higher. Got some 2,5'' stainless pipe and a lextek can, changet it's inlet from 51 to 63mm and fabbed up a new downpipe. Can't wait to ride it again

-

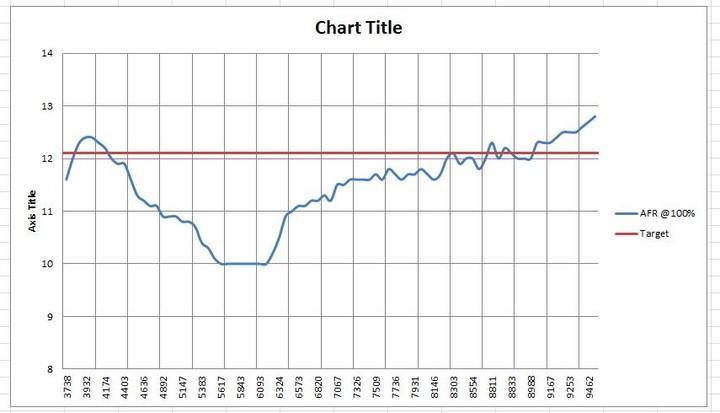

Hi, i set up my bandit myself, with very little knowledge, it's been very educational on the carb side. Do you have this AFR troughout the whole (boosted) rev range, or does it lean out in the higher rpms? If the AFR curve is flat then fit 005-010 bigger mains and you should be fine. While i tuned mine i saw that the afr is changing from (lets say) 13:1 with 115 mains To 12:1 with 125 mains, so after that it was easier to choose a main jet ballpark. If the mixture leans out in the higher revs (as mine did) then try to move the pitot tube inlet to a different place in the oncoming airflow. Rising the fuel pressure has very little effect on mixture, it has to be as low as possible and as high as needed :D

-

I've got this one. Bought it to match the dynojet wideband gauge. It's mechanical and needle shakes like hell, I only get decent readings when bike is at full boost. Thing was like 6x the money of the previous glycerine filled one....

-

i used the water drain pipe that lives inside the tank. Just cut it with a hacksaw blade from filler hole, and plug the hole on top. Easiest way, but on the downside you might get some rain/water under the filler cover, that might get inside your fuel

-

I meant the vacuum hose to the fuel tap, and blank off the other end at the carb. Don't rely on stock blank off nipples because they will fly off with boost, use somekind of a clamp over them. Also use rubber mounts/dampeners from stock oil cooler to fit the new one, it wants to move with changing temps. My cooler sits very close to the frame, to give R1 forks room for full lock.

-

Stock bandit fuel tap is vacuum operated, just disconnect the hose and set it to PRI. Flow is sufficent

-

my 1216 @10psi and td04 has 125 prox ones in it. Afr is 11,5 at full throttle

-

It made 10.7 last year, probably thanks to new lower suspension. Will be aiming 9's this year with the longer swingarm

-

The bike is still going strong. Waken from winter-sleep few days ago. Having some issues with too rich condition. It has not been dynoed still, but has had some suspension upgrades and 4'' extended swingarm with 6'' Tlr rim at the rear

-

Mine's has been running for 2 years now. I guess the pipework is overkill, but i've had no leaks since fitted those, and it looks good

-

After messing about with the carbs in september i noticed that bike doese'nt like starting with choke anymore. Usually when starting up cold engine i pulled the choke fully on and everything was like it should, the same when it was NA (revs rising and slowly backing off, til it was warm enough) Now it starts with choke but seems to flood the engine (afr gauge drops under 10:1) in few seconds and stalls, if i back off the choke, then the revs are too low and it stalls again. Only way to get it warmed up is to start with half choke and play with the throttle, same time closing the choke circuit. When its warm, then all is good. Cleaned the carbs, checked for leaks in needle valves, plugs all look the same color. Tried with fuel pump turned off, but nothing. I'm out of ideas. it can't be because i lowered the needle by two clips?

-

Problem solved. The o-ring under the carb top was blocking the signal to dump valve, and it was probably leaking. For peace of mind i cleaned the lot, checked float heights and measured fuel pressure. Now its between 11 and 12 all over the rpm range (on full throttle) Cruising is 13.5 and idle 11.5

-

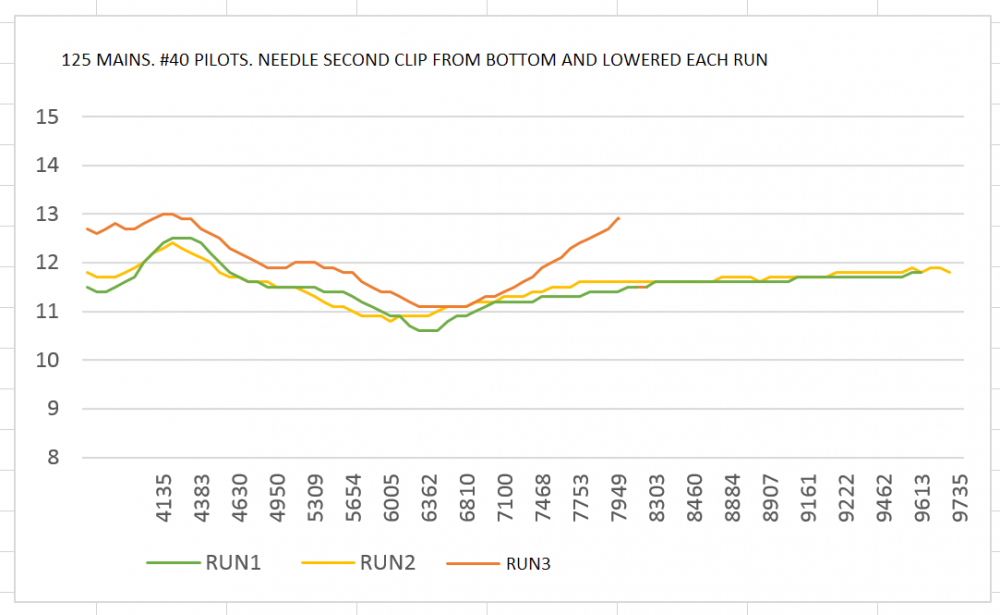

I raised the needles back to the center groove, but this problem stayed, it starts leaning out after 7000 rpm. I'm going to strip the carbs and give them a good clean, and assemble with most care. There has to be something wrong, because this setting (RUN2) worked fine before

-

http://www.Eblag.com/itm/Suzuki-GSF1200-Bandit-MTC-1216-Turbo-Pistons-81mm-/252015586383

-

Can't lower fuel pressure, it will starve on longer under-boost runs, it's about 2,5-3 psi. So, i did a fresh ''pull'' and that's RUN1, not too bad (richest was 10,6). Then started to lower the needle, mains seem to be ok. In the center groove it was better (RUN2), no change in top end (richest was 10,9). But lowering it again did THIS (RUN3) made midrange leaner but wtf happened to the top end? Also noticed that cruising ( 60mph) AFR was changing big time because the needle position: RUN1-12.5 RUN2-13,4 RUN3-14,3 What should be ok for cruising?

-

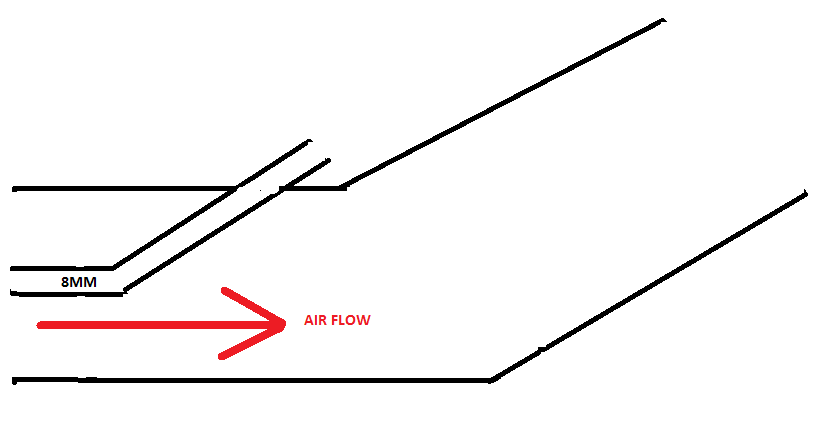

HI, i've been riding my 1216 Bandit with td04 for two years now, but i think my air/fuel ratios could be better. Look at the graph, and you'll see what i mean. Bike has never been to a dyno, i'm using dynojet wideband commander to log it. It has mikuni bst36ss carbs with 125 mains and #40 pilots, needles are somewhere in the middle. I tuned it first at full throttle, to get the best mains and afr under 12. Then fiddled with needles and mixture screws to run smoothly. It is running good, no smoke or coughing, comes on boost nicely. Works fine and pulls hard, but i'd like it to be spot-on. By the time this ''pull'' was made, i was running 7psi, but now 10 and it's a bit richer everywhere (under 12 at full throttle), but the curve has the same shape. Any suggestions, to get that rich spike out? Is it the tune or system design? (bottom pic is pitot placing before the plenum)

-

-

I use 3 of the carb top take-off's for FPR, BOV and Boost gauge, one is left closed. For the wastegate actuator I use the take-off on the turbos compressor side (with controller in the line)

-

interesting, i've always used 18mm socket. U need the socket to be with thin walls, to fit into the head

-

Sorry, have'nt updated this topic lately. It starts now, as good as before turbo. With choke when cold and without when warm (bit of throttle helps) I've messed with the floats, mains, needles, pilots, fpr..... with everything possible I guess. I have'nt had any problems with flooding, fuel pump starts with the ignition turned on. I'ts set up now and running fine at 10psi, still not dynoed for power figures. Could do some fine tuning, but at the moment it's 90% good. I strapped the plenum to the head after it blew off at 10psi / 120 mph, that was scary.... I have ridden it for 1300 miles this year without any massive problems, some leaks and minor problems, but it's still work in progress and every ride is a test ride Header and other stuff is from Pete Triplep Also here's a pic of it doing a 11.3 run. Not too fast, i know, but stock swinger, shitty track and lack of skills are to blame.

-

I know that i have to take the feed from the same plug as the turbo, then it goes up to the two plugs on the right side of the head. But what about the left side? Do i need just connect the two plugs to each other or connect it to a third place?

-

got the new cooler Open road Dyno Some billet carb tops, also all phillips head screws on the carbs are changed for allen/hex type screws for reliability (rocker cover needs paint, yes i know) )

-

So i fitted a turbo on my B-1216, also the engine's got APE studs that are thicker than standard ones. Do I need external oil feed to the top end? Just asking because (I guess that) turbo oil feed takes some of the oil pressure away and thicker studs may not let sufficent amount of oil to the top. I know that cam to cam links are basically pointless, but can someone share a picture of correct setup that actually works. Cheers

-

Hi there. You have done your homework correctly, stuff you are writing is correct (because i have the same setup, and it's proven to work) Dropping the CR is strongly recommended and using forged pistons (busa) Some say that you can run stock engine up to 12psi, but better safe than sorry. So I would go with busa pistons and rebore to 1216. If you use busa pistons then you dont need to use a spacer under the barrels, because the pistons are lower than standard ones. Standard blandit diaghpram type clutch won't hold much more than 150-160 whp, so either gsxr coil type conversion or lockup. I installed lockup, it holds great so far (at 6psi) feels just like standard ,easy to pull clutch, but it won't disengage above 6500 rpm Sorry but I know nothing about efi conversions Btw i'm no oil-cooled/turbo genius, just the info i have been gathering over the past year of ''homework'' and 2 months riding a boosted bandit

-

No check valve needed yet, I let the oil pump run a bit after shutdown. Also its on side stand, and thaks to jack-up at the rear, the bike is more leaned over on the side stand. I havent seen any blue smoke after starting, but some black smoke when flooded. Bike still needs setting up, it's running too lean. I reached some scary numbers under boost (13-14,5). And needs new smaller oil cooler, the standard one doesen't fit correctly with those headers, and started to leak from the crimped hose. Also, do you have any reccomendations to start the bike better when cold? Before turbo it was okay: choke and it sarted normally. Now it wont start with choke, it needs playing with the throttle and doesen't want to idle without giving it some revs, after a minute or so it starts to idle normally.