Maxxii

Members-

Posts

30 -

Joined

-

Last visited

Reputation

1 NeutralPersonal Information

-

Location

Toronto Canada.

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

So I can pull it out, tap it for my sensor, and put it back in? Or pull it to add oil line. Great! That solves my first temp sensor placement. Where do you normally get the oil lines from? What I mean is if you use those points to feed more oil to the cams, where do you get oil pressure from? And could I use that for the second sensor?

-

Oh, you mean the one in that bolt in my first picture? Is it safe for me to take out that bolt and tap it? It's not gonna let something loose in the valve train, is it?

-

Which ones on the side of the head? I don't know which one you're referring too. And is there anything in the sump other than the drain plug I can replace with a temp sensor?

-

I had no idea that jb weld was mostly plastic. Both of the sensors are the same I don't really need the readings to be perfectly accurate. I just want to set an over temp warning on the koso clock so that I don't over do it. I can adjust the warning setting to what ever I want. So if the temp sensor is insulated, I can simply lower the warning level. So I can kinda calibrate for that. I don't want to drill into the casting if I don't have too. Even though it's aluminum, I don't have the right drill or bits to do it right. Might there be an auxiliary oil port or something that i can tap into? I don't mind drilling into a blocked off auxiliary oil port. But not into the actual cylinder head. I'll measure the sensors when I get home. Ideally, I'd be monitoring cylinder head temp, and oil temp coming out of the radiator.

-

I've got the engine and clutch swapped. And put a koso clock on her. The clocks came with 2 temp sensors. I was thinking of mounting 1 of the temp sensors to the cylinder head, and use the other as an air temp sensor. Is there a part of the cylinder head that I should mount the temp sensor too? I'm not looking for a bang on perfectly accurate reading. But more of a general over all temp. I thought I'd jbweld the sensor in place. How does this sport look? What do you fellas think?

-

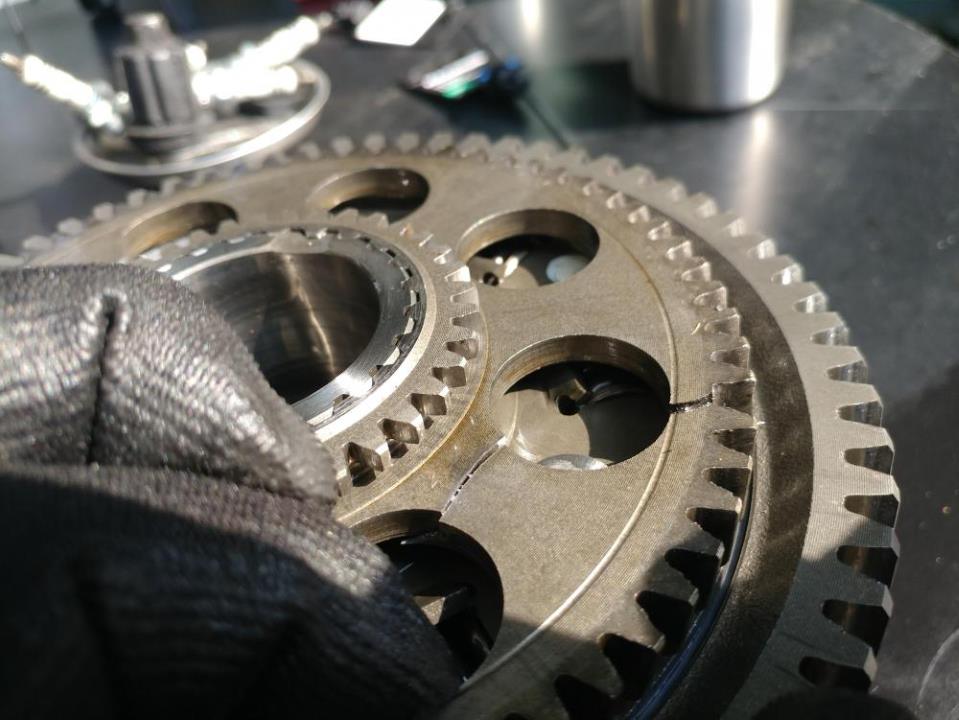

Last update for the night: I put the gsxr outer basket(with the straight cut gears) back in the gsxr engine(which is in the bandit frame. I put the bandit inner basket(the dark gray one in the pictures above) in the gsxr because it's in much better condition. I double checked the washer/spacer orders, and torqued them both down. I put the clutch pack back in, added the top plate, springs and bolts, and torqued them down too. Before I put the side cover back on, I want to check which of the push rods is the right one. The difference in size is a couple of mm but I want to make sure I have the right one. Someone had already commented telling me not to mix them up.... I mixed them up.. So I tried putting the chain guard from the bandit engine back on, but it's sitting funny. It's got the spacers both in the right spot, but I ran out of sunlight so I had to put everything away. Just before I closed up shop, I scrubbed the chain guard clean so I could get a good look at what's wrong. So tomorrow, that's job number 1. Then I button everything back up, add oil, throw on the carbs, redo all of the electrical, and see if she starts! (and hopefully doesn't blow up ) Wish me luck.

-

-

I see. Once I get it further into her I'll have a better idea. But there's another problem. Clutch basket on the bandit has angle cut gears, and the gsxr has straight cut gears. Is there anything I can do to swap the gears from one basket to another?

-

update: got the engine back in the bike. I made a quick pair of A frame stands, and à barbell across them. Rigged up a pully system, tied a cradle around the engine and hoisted it up through the frame. Then with some wiggling, and grunting, help from my dad, and a car jack, I managed to get her in. When I took down the clutch on the gsxr engine, I found that the clutch basket was pretty badly grooved. I'll be swapping the clutch baskets tomorrow. Everything else seems to have fit perfectly. Also, I don't know exactly how it's all connected, but when I spin the inner clutch basket ring on the bandit engine, it's very hard to turn and grindy. But on the gsxr clutch basket, it spins smoothly with little to no resistance is that the transmission I'm spinning? Or is it the crank? There are no spark plugs in either engine yet. If spinning the inner basket on the bandit motor in neutral with the plugs out is really difficult, does that mean that my problem is something to do with the crank? Before I took the bandit engine out, I did a compression test and got ~150 psi on every cylinder. So I don't think it's the rings.

-

So I've got both engines out of the bikes. Can anyone sugest the best way to get an engine back in the bike alone? To take it out, I loosened all of the bolts holding the engine, then laid the bike on its side, and sort of shook the engine out of the bike.

-

Gonna google it now.

-

Swapping the electrics is easy for me. I have never seen the pickups. And I'm worried about oil leaks from opening the cover and closing it. Also, I just realized I don't know any of the torque specs. Not for engine mounts, exhaust headers, case screws... Anyone have a chart?

-

Instead of swapping the ignition pickups, could I use the gsxr harness, CDI box and stuff? Or is there a benefit to using the 1 or 2 pickups?

-

I do have to get a better appartement and job ! Anyone hiring?

-

Single, sir. No wife to nag me to sell the bikes.