I regularly bore you with how OSS is something of a community and how we help each other out. I tell tales of how parts are sent across the globe just to get someone’s bike on the road, more often that not an exchange between people who never even met. It makes for a good story, but wouldn’t it be even better if I just show you what OSS can do?

Kev and I met in a field in Burton, 2014. A longterm member was having her birthdayparty and a whole bunch of OSS-ers were attending. I just got my 100€ 1100-G going and thought it be a laugh to just randomly turn up without telling anyone I was coming. Totally worth it..

I went to a party knowing full well what to expect and having met just about all the people there before, so it’s not really diving into the unknown; hardly an adventure. How different would it be if you choose to go to a random party you saw posted on FB, knowing near-0 people there, going to an OSS-do as a through-and-though Kawasaki fan but owning the most colourful B12 on the planet? Cue Kev.

He fitted right into our merry crowd of Suzuki-fanatics and it didn’t really take that long for us to make him see Suzukis really are better. He’s still building his Zed, but more on that some other time.

Me and Kev personally really hit it off. So much so that I attended his wedding not a few years later, along with a fair few people that were also present in Burton that weekend in 2014.

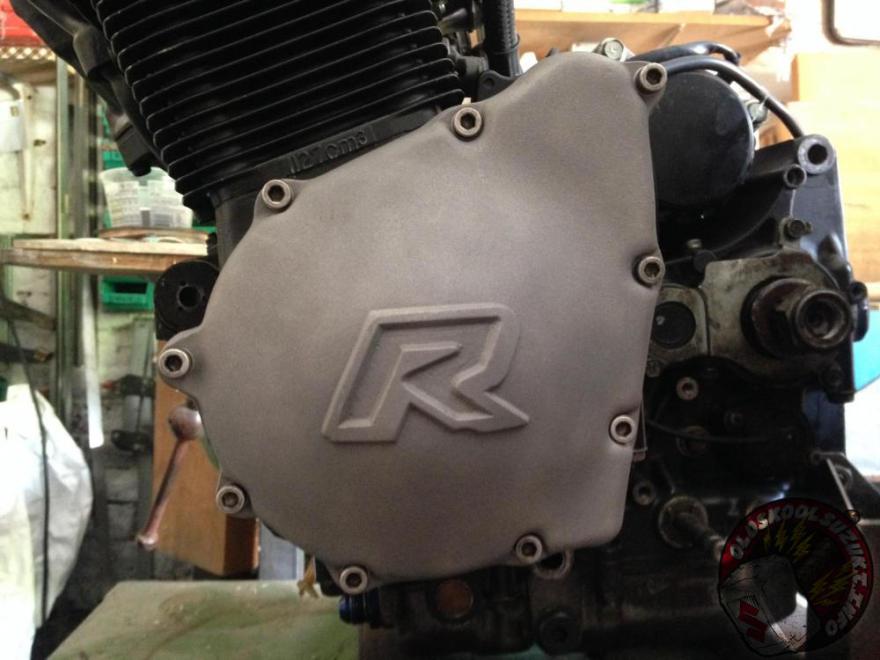

Over the years Kev had been playing with the thought of building a bike for his better half Jess and she suggested/asked for an EFE, because after he sold the B12-powered one he had (and crashed) a while earlier, the EFE shaped hole in their life was too much to bear. Mistakenly selling it, the deal was regretted for long and with parts few and far between, and prices for those parts on the up, the idea of building one stayed that; just an idea.

But, when you have OSS at your disposal, sailing the unforgiving seas of OldSkoolSuzuki-unobtanium becomes a ferryride across the Mersey river, a frame was acquired from PaulM to kickstart the build and it didn’t take long before other integral parts for the build were starting to turn up.

Me being me; I didn’t know what to get the couple for the wedding, so I took EFE-bits, happily received and put to good use a few months later when we chose to build a “bike” in a day over newyears. This is still start of 2019.

DaveCara supplied the enginemounting kit which was welded in place, we flung some engine in from a distance, bolted Kev’s old turboheaders on it for good measure and there was something there resembling the endgoal. I went home, 2019 got underway and Kev and Jess went on to do the project as anyone tackles a project, while keeping a normal life, entertaining a child and keeping everyone fed; slow and steady.

Taking no shortcuts, all was done properly; powdercoating, some pro modifications to the JMC swingarm borrowed of Dad Kearsley, some things even got 3D-printed (posh) and wiring was done in the kitchen, as you do.

All pretty normal, and then Covid came. The whole world grinded to a abrupt halt, leaving many of us wondering what to do. No need to go to work and no option to go anywhere fun, Kev got the project on the rails properly and steaming to the finishline. Making good use of daytime tinkering, the bike went from “It’ll be done in a few months, honest” to, “It’ll be done in a few weeks, really”.

The world is still a bit strange with not being able to move around as we were used to, but if this whole historic episode brought one thing positive, it’s having yet another EFE back on the road. Time that was usually wasted on working for the man, was put to good use in the shed. With bits sent from all across the UK and beyond, this bike is a good show of force of what I mentioned all those times before and I’m proud to have played a small part in it.

Now, if all goes back to normal, I could actually go see it but until then, this will have to do.

Congratulations @Kid Kearsley and @MrsKid, you EFE is this month’s Bike of the Month

Buildthread here

Discuss here